Top 10 Merits of Employing Plastic Injection Molding Services

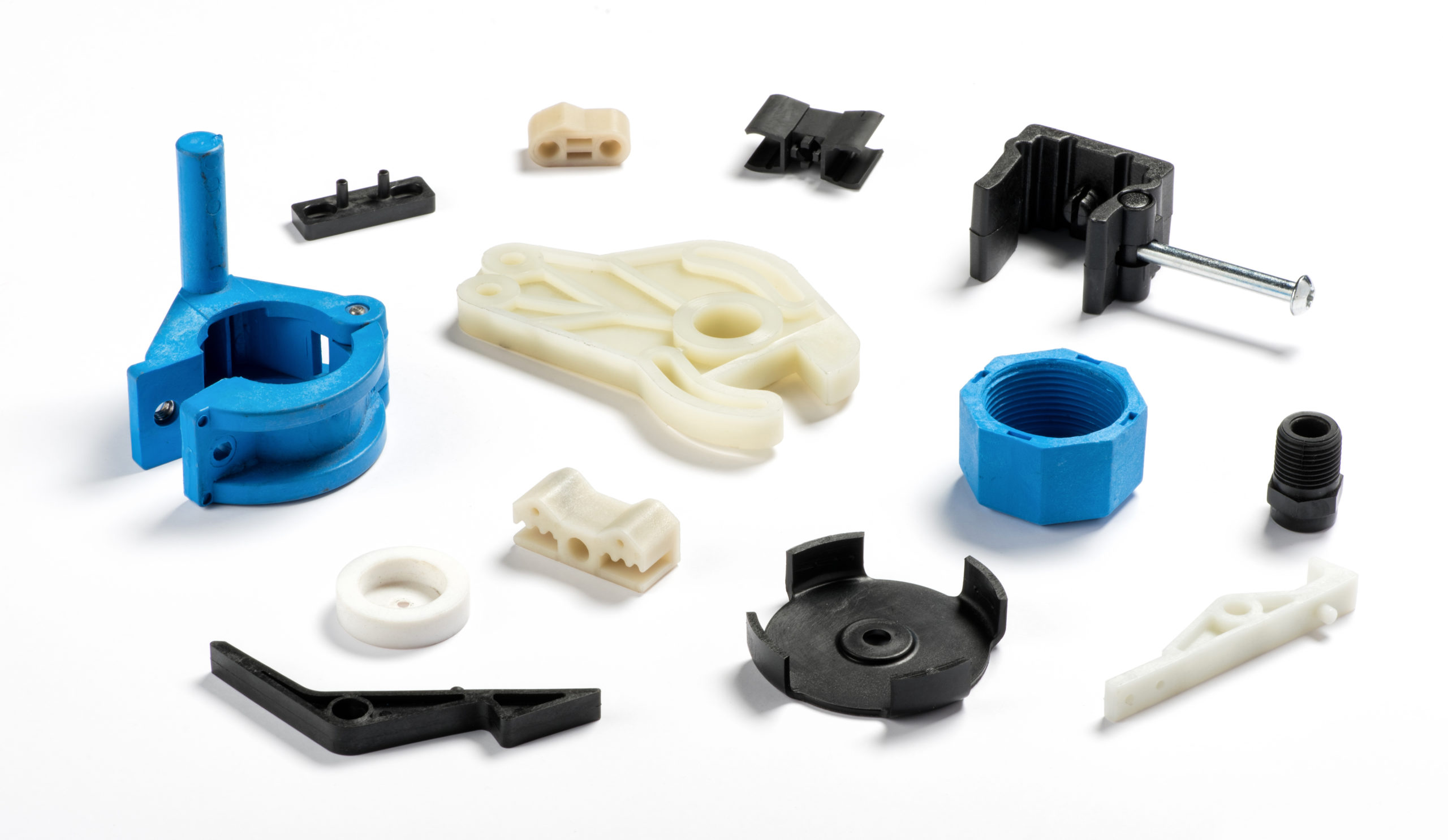

In this modern fast-paced production ecosystem, organizations are continuously seeking optimal and economical ways to manufacture premium items. One of the most effective approaches available is injection molding service, a technique that permits manufacturers to assemble intricate patterns and a substantial volume of items rapidly. This process involves feeding heated plastic into a form, where it hardens and sets into the desired shape. Due to its flexibility and exactness, plastic injection molding has turned into a popular selection across multiple sectors.

Employing plastic injection molding service offers numerous gains that can dramatically enhance manufacturing processes. Including reduced waste and increased design flexibility to speedier turnaround times and lower labor costs, this manufacturing method is a revolution. As more companies realize its merits, comprehending the main reasons to leverage plastic injection molding can assist companies make smart choices that lead to streamlined operations and better goods.

Pricing Effectiveness

One of the main benefits of utilizing polymer injection solutions is expense efficiency. This manufacturing technique allows for the mass fabrication of goods with minimal waste. By using precise molds, manufacturers can create identical pieces in large quantities, which significantly lowers the cost per unit. The efficiency of this approach means that businesses can achieve cost savings, making it an appealing solution for companies looking to cut production costs.

Another aspect that contributes to cost efficiency is the quickness of the plastic injection-molding technique. Compared to traditional manufacturing approaches, molding can create pieces at a much swifter rate. This rapid production capability means that companies can meet higher demand without further labor expenses. Less resources are required to produce high volumes, allowing organizations to reassign their funds towards additional important areas such as innovation or marketing.

Moreover, polymer injection-molding solutions often bring about decreased material prices. The process typically needs less raw material than other manufacturing approaches, as it limits scrap and waste. With advancements in innovation, the choices for affordable materials have also expanded, allowing producers to choose the optimal material for their particular needs without increasing costs. This mixture of speed, efficiency, and material cost reduction results in a production method that is both economical and sustainable.

Design Flexibility

A major benefit of utilizing plastic molding services is the exceptional design adaptability it delivers. Designers can experiment with elaborate shapes and sophisticated geometries that are frequently challenging or impossible to achieve with different manufacturing techniques. This allows for creative product designs that can fulfill defined functional requirements, while also improving design appeal. The adaptability of injection molding guarantees that both traditional and tailored solutions can be produced efficiently.

Integrating innovative design software with plastic injection molding processes also facilitates rapid prototyping. Designers can build prototypes to test and improve their concepts rapidly before advancing to final production. This repetitive process not only conserves time but also minimizes costs associated with tooling and material waste. As a result, businesses can modify designs in replying to market feedback, making sure that the final product matches with consumer expectations.

Moreover, plastic injection molding can accommodate a wide variety of materials, which contributes another layer of flexibility to the design process. Different polymers can offer distinct properties such as resilience, bendability, or heat and chemical durability, providing tailored solutions that cater to defined industry needs. Whether it’s a sophisticated component for the automotive sector or a minimal part for consumer electronics, this service can adjust to meet a varied range of applications.

Rapid Production

Synthetic injection molding services are renowned for their ability to produce large volumes of parts in a brief time frame. This rapid production ability is essential for businesses that need to satisfy high demand without compromising quality. The process is engineered to work effectively, allowing manufacturers to create a multitude of identical parts in a short hours. This not only helps in aids in satisfying tight deadlines but also significantly lowering labor costs linked to manual production methods.

Furthermore, once the first setup of molds is done, the real injection of plastic is speedy and consistent. The robotic nature of plastic injection molding limits human error, thereby increasing the speed at which products can be produced. With shorter cycle times, businesses can quickly launch new products and make adjustments based on market feedback, keeping them competitive in a fast-paced landscape.

Moreover, the consistency achieved through rapid production ensures that each part satisfies the required criteria and quality standards. This dependability fosters customer trust and satisfaction, as clients can anticipate the same high-quality product with all order. As a result, businesses can focus on expanding their operations and boosting their market presence, confident that their injection molding solutions will aid their growth effectively.